AA. What is Thermal Imaging?

Thermal imagers register and display Thermal patterns across the surface of the object viewed. These patterns cannot be seen by naked eye as they are at a higher wave length than the visible range.

BB. What is Ultrasound?

Ultrasound machines detect sounds in the range of 20 to 100 KHz which are not audible to human ears. These high frequency sounds are heterodyned and made audible by UE system probes.

Advantages of using Thermal Imaging and Ultrasound are:

• Condition analysis of applied over Mechanical, Electrical and Hydraulic applications

• Non-intrusive testing and safe to implement

• Improved Safety and Reliability

• Energy savings and ultimately cost saving

• Minimize trouble shooting time

Our Integrated inspection is comprised of using Thermal Imagers, Ultrasound probes and Vibration analyzers.

CC. What is Vibration measurement?

Every machine or appliance whether it is reciprocating or rotating has vibration induced into itself due to its own characteristics. When it is working in good condition, the vibration is within limits. The control of vibration is only possible by measuring it.

Advantages:

- Predicts machine failures

- Helps to plan repairs

- Reduces downtime and brings cost savings

- Assess the condition of the machine

DD. WHY WE RECOMMEND TO CARRY OUT INTEGRATED INSPECTION

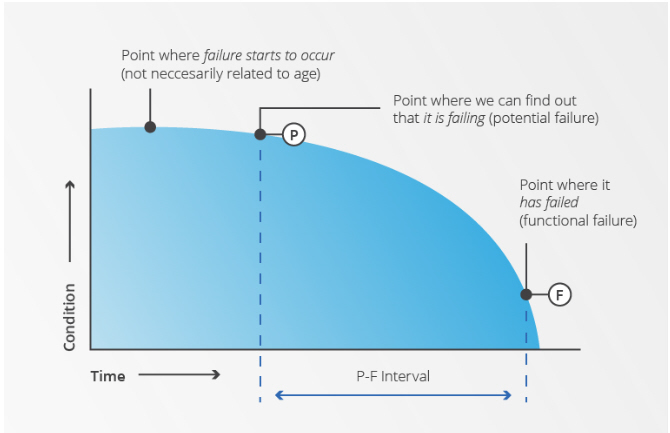

Ultrasound identifies problems at an early stage of failure. Vibration system identifies the abnormalities at a later stage. Thermal Imaging is the last stage of failure identification.

Depending upon, where the problem is identified, the cost of repair proportionately increases. All the above can be clearly seen from the PF curve produced below.