| J. Rajagopalan Chief Executive Officer Mob: +65 98637870 AOH: +65 69885294 email: Raja@svlsingapore.com swmera@gmail.com |

| • Condition Monitoring • Vibration Analysis • Ultrasound Survey • Thermal Imaging Survey |

• Ship Pre-purchase Inspection • Predictive Maintenance Survey • Energy Technical Audit • Marine Technical Consultancy |

Presentation

| SVL SINGAPORE SERVICES RAJAGOPALAN. J Blk 609, Unit 05-174,Elias Road,Singapore 510609 |

Integrating Infrared with Ultrasound and Vibrations analysis applications for Marine and Offshore Industry |

|||

Predictive Maintenance is the use Non-intrusive Technologies of Infrared Thermal Imaging, Ultrasound Detection & Vibration measurements. |

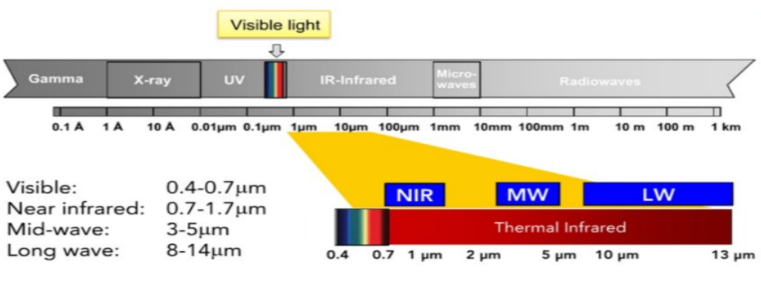

Thermal Imaging: With the Thermal Signature, we can see the Infrared Radiation which we can not see otherwise |

|||

What is infrared? |

||||

|

|

|||

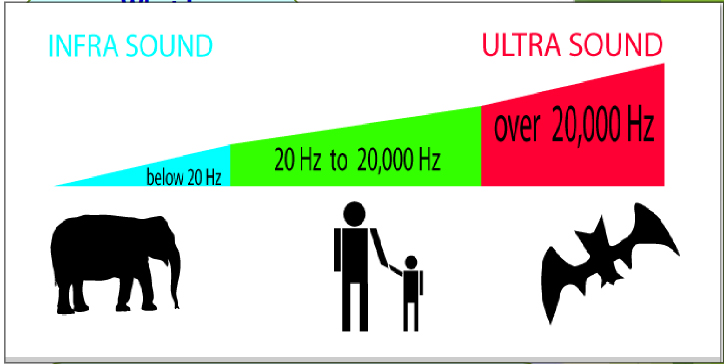

What is Ultrasound? |

||||

|

Human range (16Hz to 18KHz) |

|||

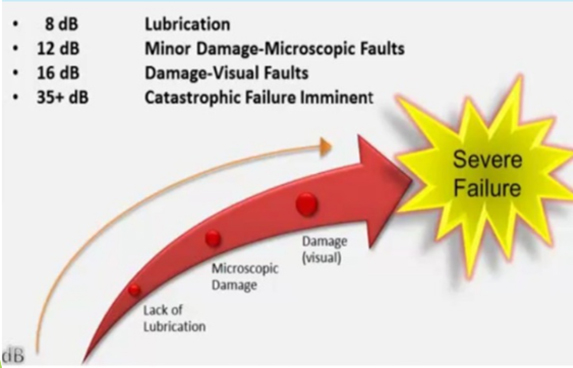

Levels of Severity With ultra sound |

||||

Above baseline 20 dB

|

||||

|

Mechanical Inspection |

||||

|

||||

Some problems that can be detected with Ultrasound, Infrared & Vibration |

||||

|

Making Motor Ready for Service

|

|||

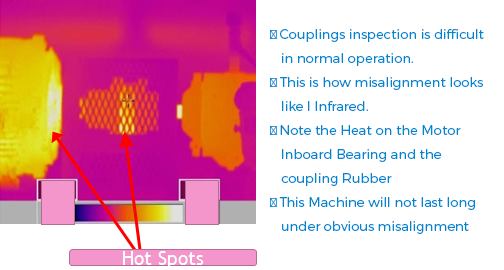

COUPLINGS AND SHAFTS ALIGNMENT |

||||

|

||||

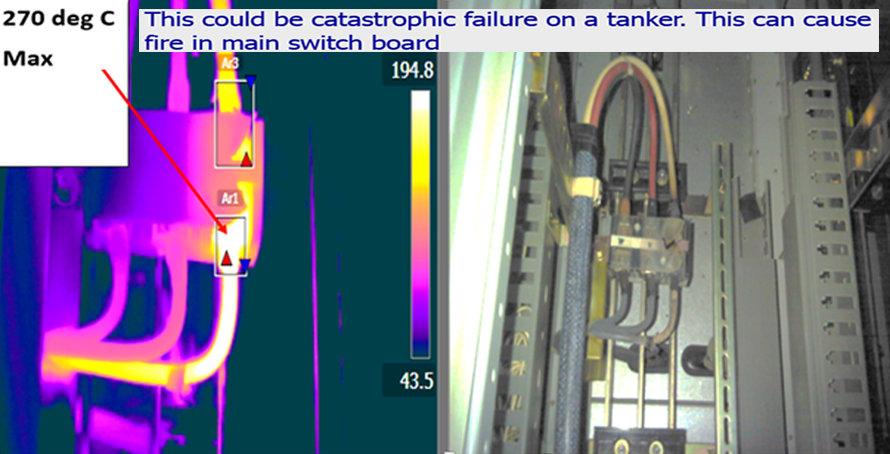

Increase machine Reliability with Infrared Technology |

||||

This could be catastrophic failure on a VLCC can cause fire in main switch board |

||||

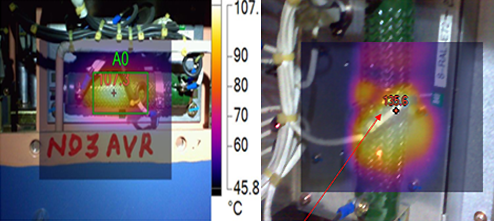

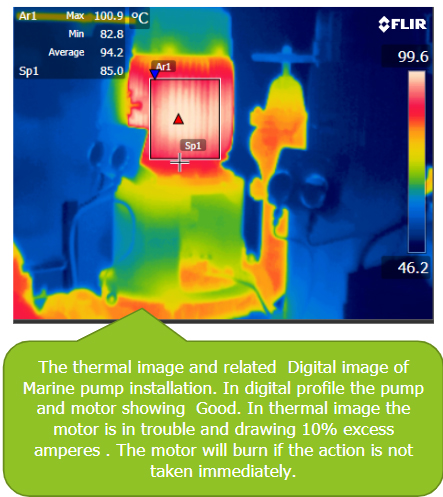

A TYPICAL MOTOR / PUMP PROBLEM - EXAMPLE |

||||

|

This photo is taken in a leading company tanker vessel and displaying as example. |

|||

|

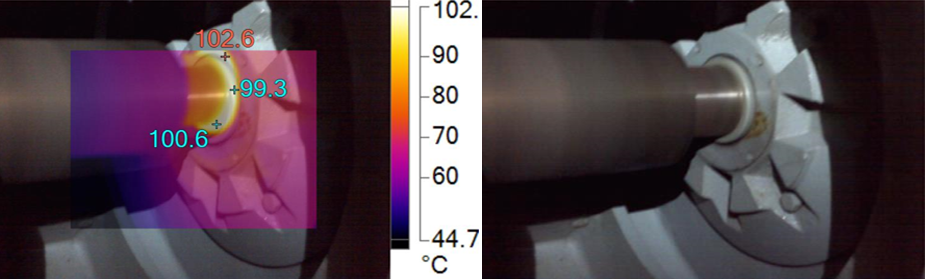

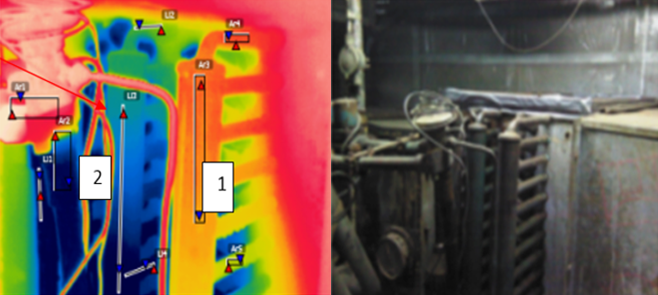

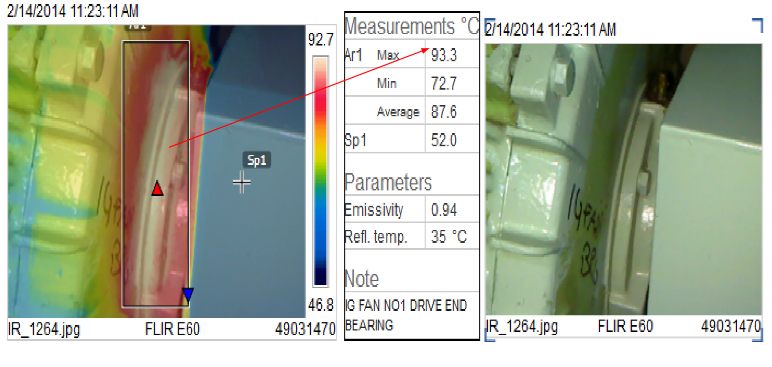

A 250 kw motor inert gas fan in a vlcc operating with drive end bearing temperature of 93.3*c is going to cause damage to motor due to misalignment and overloading |

|

|||

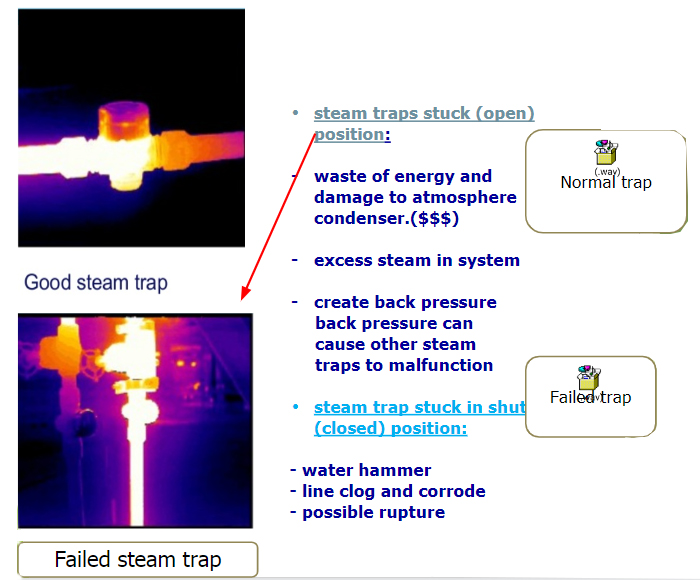

Cause and effect of failed steam traps |

||||

|

||||

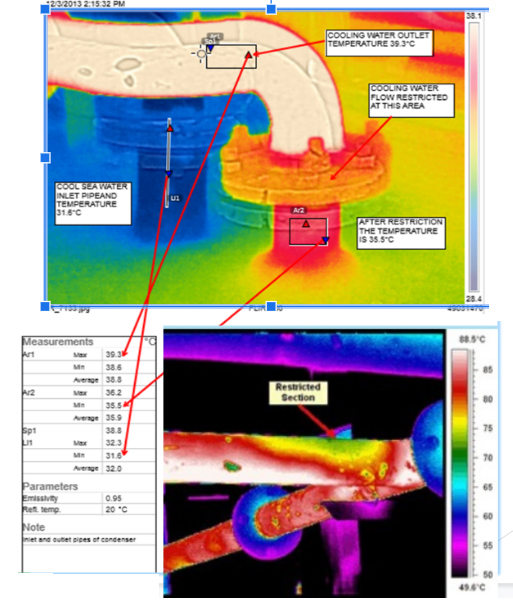

The partially blocked pipe is an example of surface temperature effects in a pipe line |

||||

|

||||

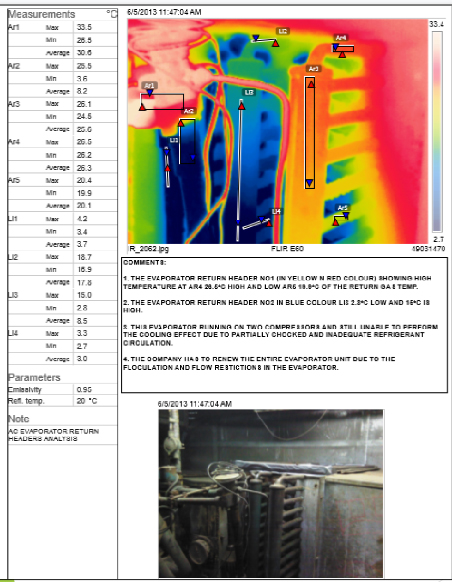

Sample evaporator liquid refrigerant inlet and expanded gas outlet at the return headers for each coil |

||||

|

Both above compressors connected to this defective evaporator coils. Loss of energy with 2 compressors running with minimum climate control effect |

|||

Main air compressor high pressure suction valves one valve is leaking badly other valve is chocked with carbon trouble- energy loss/ damage to valves, carbonisation in inter and after coolers and reduced efficiency |

||||

|

||||

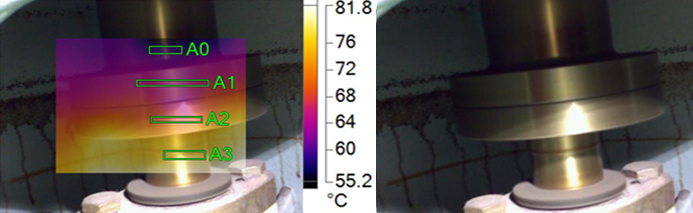

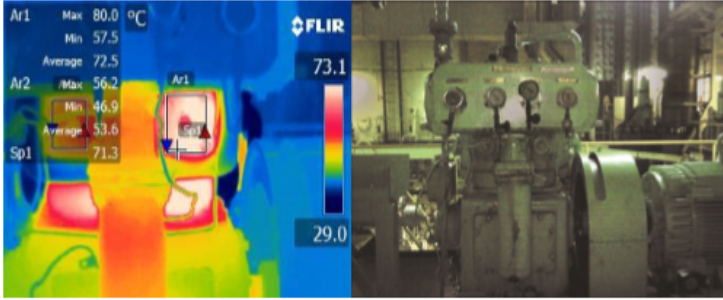

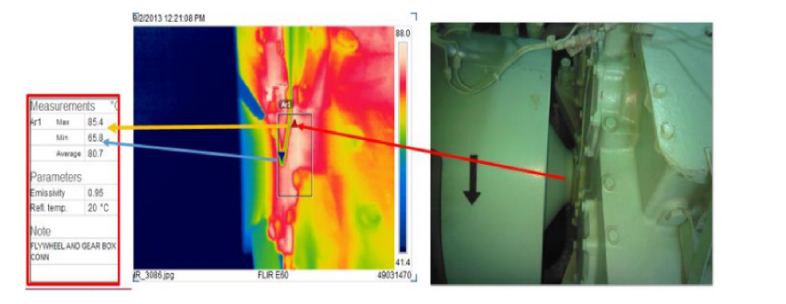

Marine Propulsion Gear box showing high bearing temperatures The Gear box drive end bearing showing 85.4*C where the Lube oil temperature at the cooler inlet 48*c indicating trouble at at the bearing condition. |

|

|||

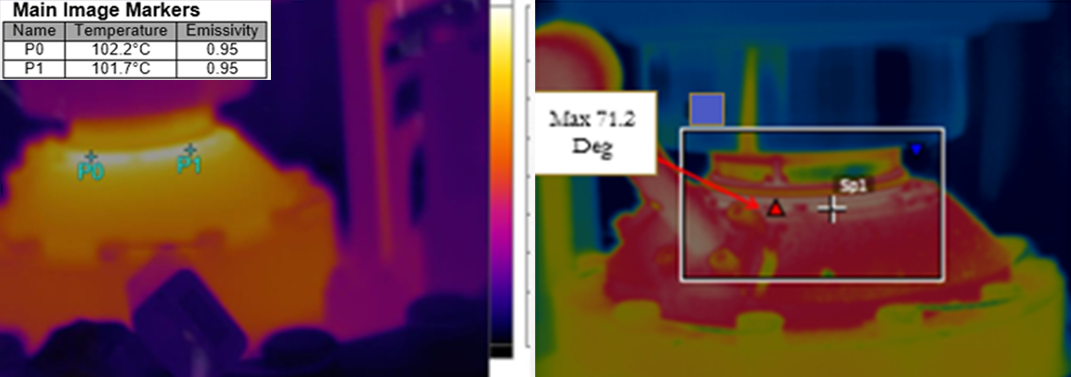

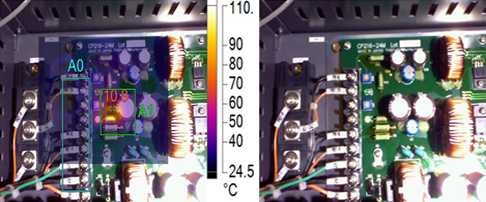

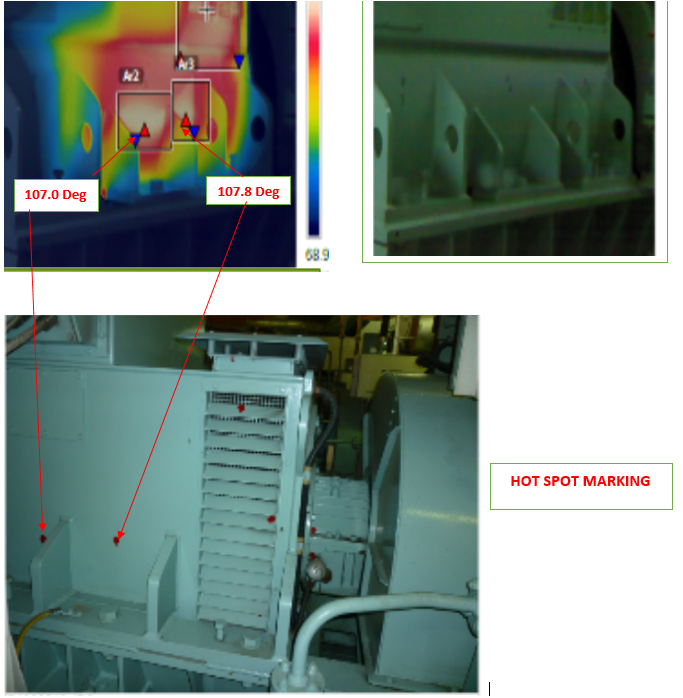

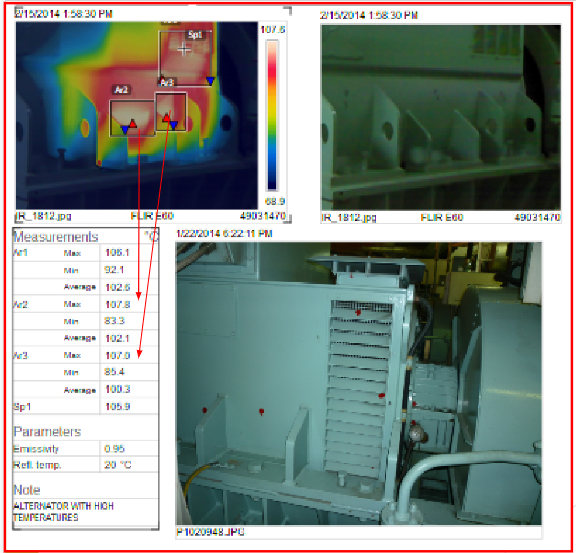

A diesel generator alternator showing high temperatures can cause damages loss of alternator life due to excess temperatures |

||||

|

||||

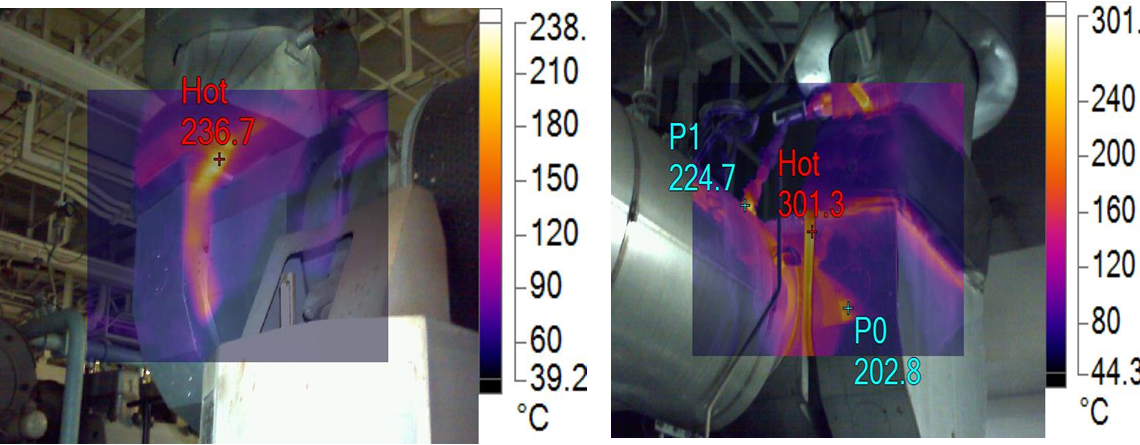

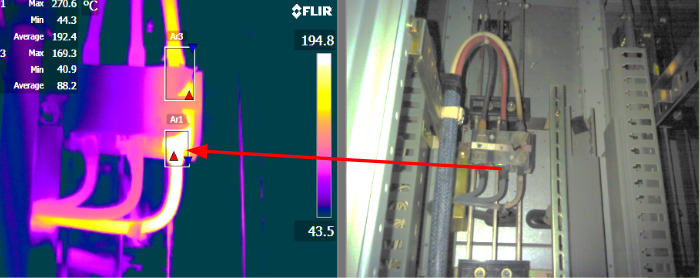

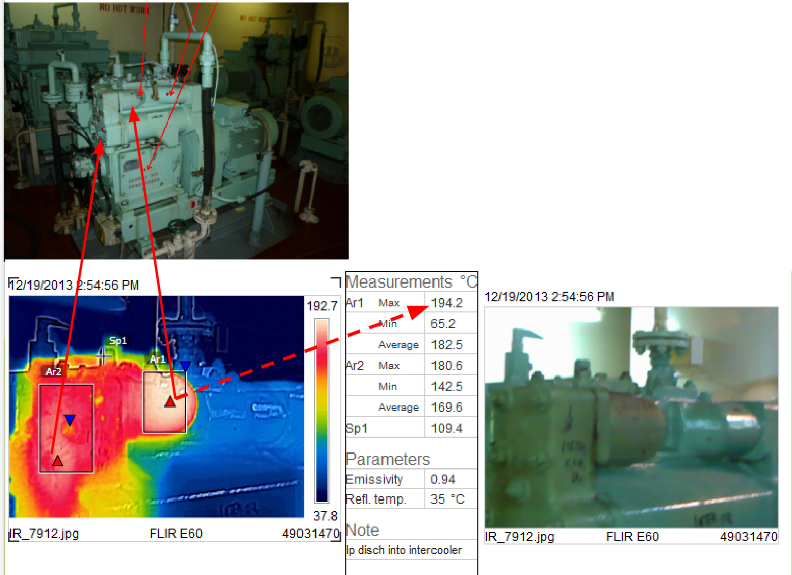

Main start Air compressor onboard running very hot with LP discharge inlet to inter cooler about 194.2*C reduce the efficiency, long running hours and damage to many components like valves, coking in inter after coolers etc., |

||||

|

||||

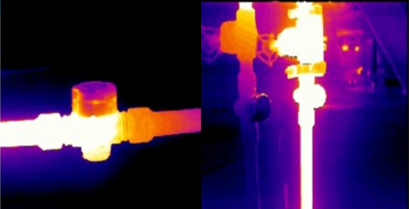

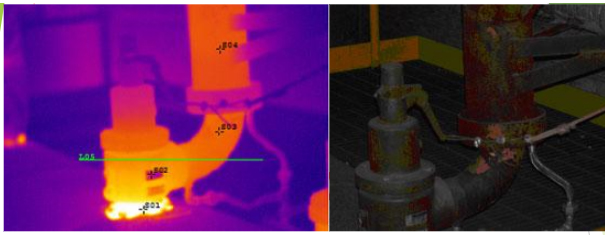

Leaking Boiler Relief valve This is not only dangerous but very costly in Steam production. This must be corrected at the earliest opportunity. |

||||

|

||||

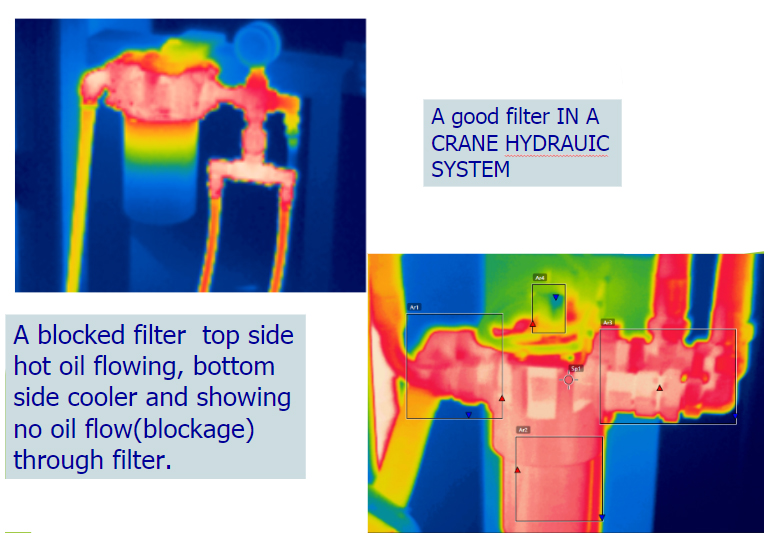

Pumps and hydraulics |

||||

|

||||

Bearing Inspection Increase your Equipment Reliability with Ultrasound Technology |

||||

|

|

|||

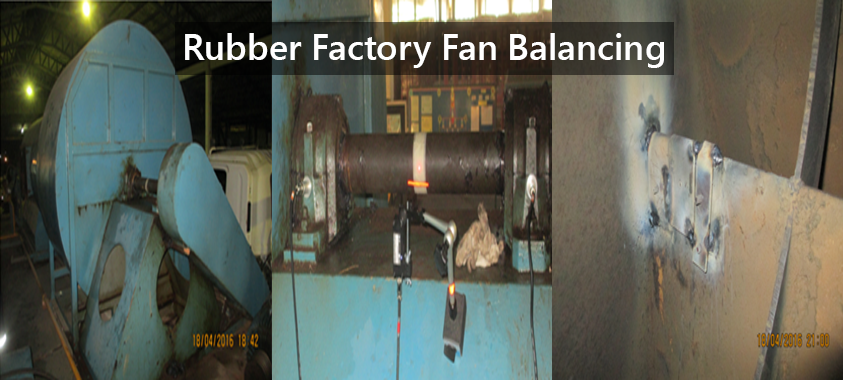

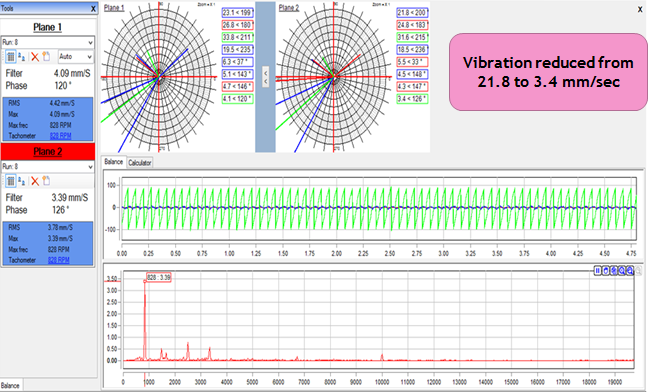

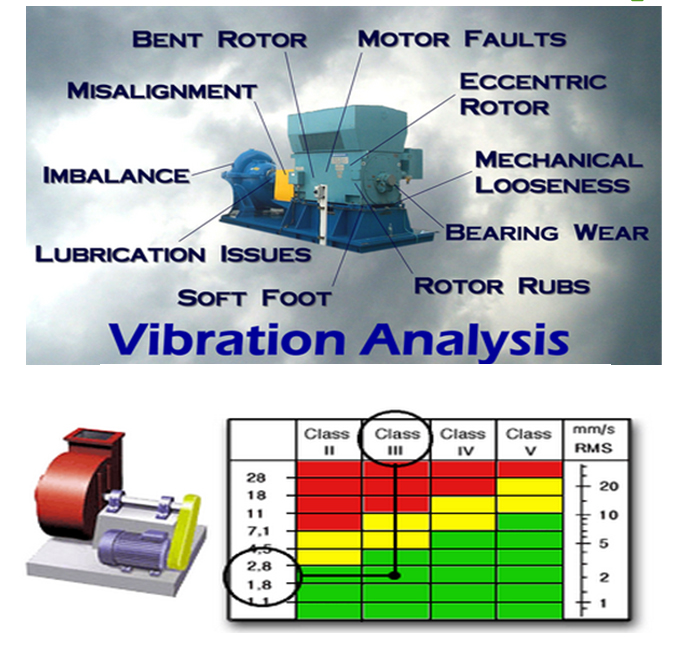

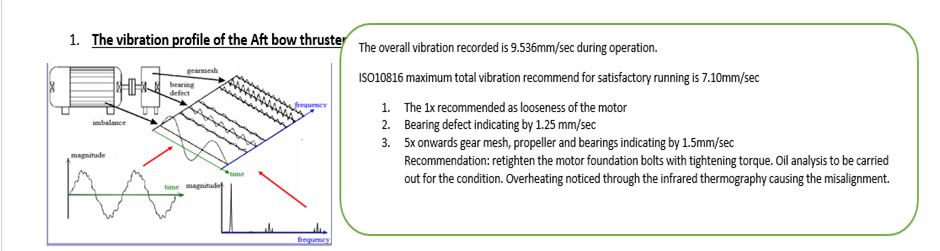

Vibrations of machinery |

||||

|

The ISO standards for the machinery vibration values limits |

|

|||

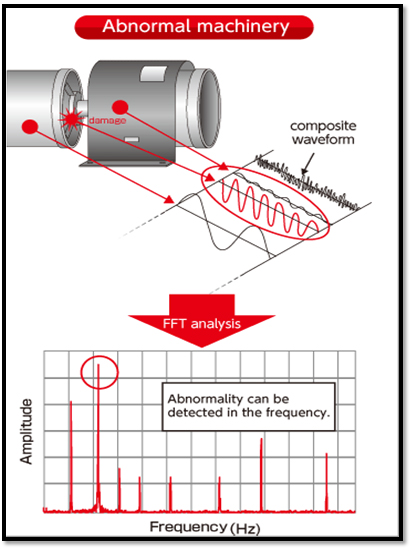

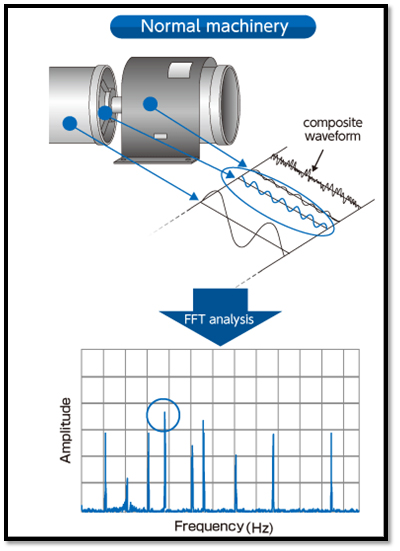

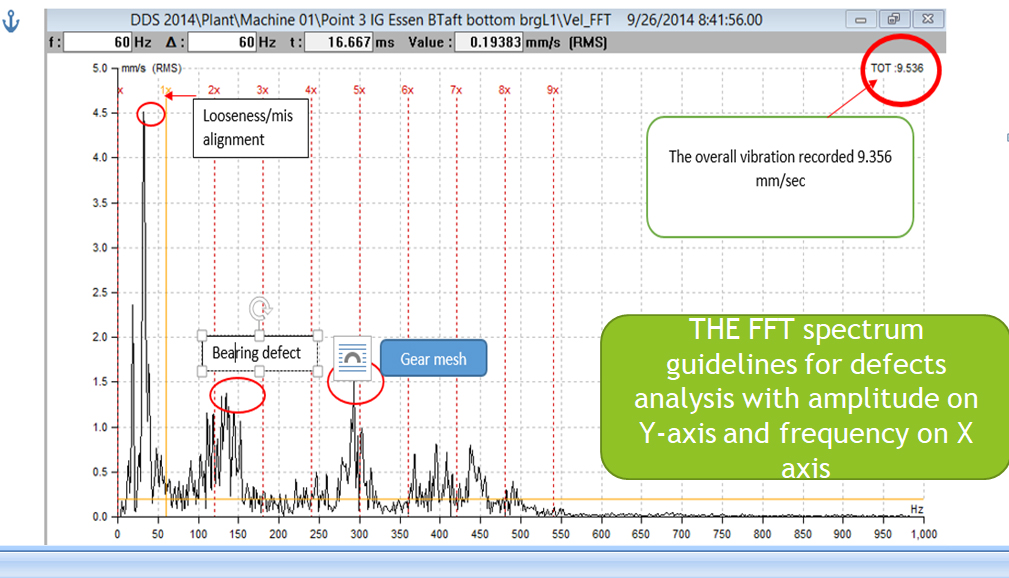

Using FFT analysis for defects |

||||

|

|

|||

|

|

|||

|

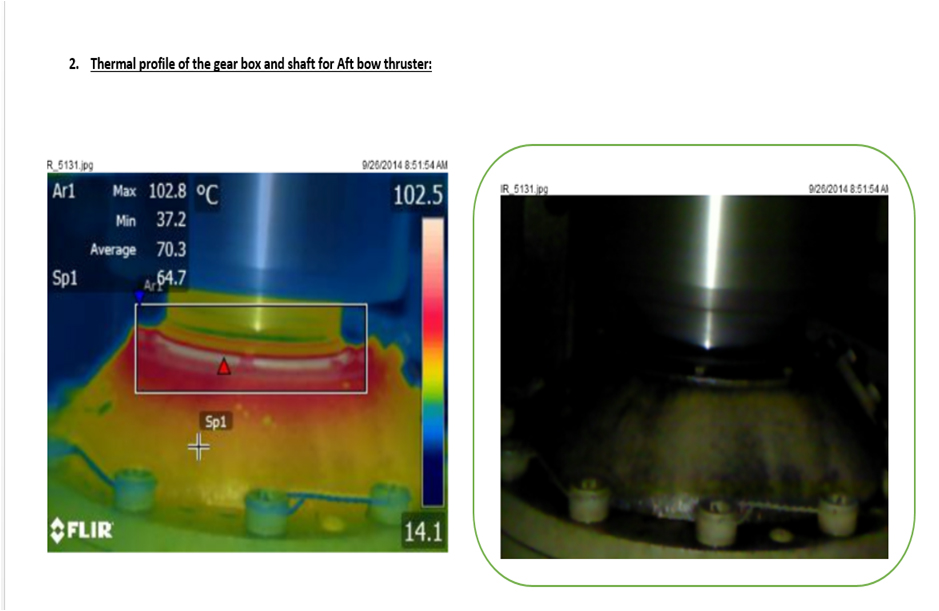

||||